Introducing ABI’s first ever loader

Overview

More than a Mini Loader

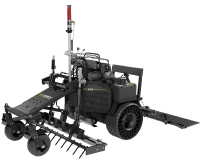

Meet the next powerhouse machine to join our Force line of products: the Force Stand-On Utility Loader. This isn’t like any mini-loader you’ve seen before. Our revolutionary stand-on utility loader gives you the power and capability you need to take on more commercial landscaping projects—big and small. This machine runs on wheels so you can lift and move materials up to 750 lbs on concrete, dirt, and snowy surfaces with ease. Built with zero-turn functionality, our stand-on utility loader allows you to make tight turns or move around obstacles better than a mini-loader. As a bonus, our stand-on utility loader is integrated with smart technology to ensure user safety at all times. For example, it features an auto-leveling bucket that automatically readjusts to stay parallel to the ground when lifting materials to prevent spillage on the operator. Work with greater speed, efficiency, and safety using the Force Stand-On Utility Loader: your new favorite loader for any season.

Attachments

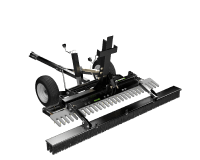

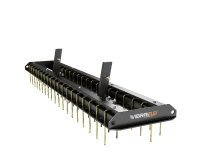

Ideal for contractors looking to make quick work of sidewalks and tight corners.

The scoop can carry up to 300 pounds of mulch or soil and place it right where you want it.

The rear soil finisher attachment will take your soil conditioning and landscape finishing capabilities to a whole new level.

Can lift up to 750lbs and comes with a default auto-leveling function.

Features

The zero-turn capability of the stand-on utility loader allows you to move in tight spots, around edges, and closer to property lines than other utility loaders on the market. Since it runs on wheels instead of a track system like in a mini-loader, this machine offers better traction to move safely on even snowy surfaces.

The Speed-lock feature prevents less experienced users from operating the machine faster than established by a facility manager. This feature ensures improved safety and ease of use for all operators.

The patented spring system allows for up to 1,000 lbs of down pressure, but builds in forgiveness, so you can power through some of the toughest jobs. With unparalleled pitch-control and hydraulic rear lift control, the ground engaged components mimic the movement of the machine to provide the best finishing results.

Each stand-on utility loader is equipped with a standard 23HP electronic fuel injection engine, which teams advanced computer controls with a high-pressure fuel delivery system to ensure peak power and fuel efficiency. The machine starts like a car with no carburetor issues, increased fuel efficiency, and easily starts in the cold!

Typically, machinery of this size runs on a Hydraulic Drive System geared to a belt and pulley drive shaft. The lifetime of a belt can be unpredictable due to frequent breaks. Force machines are plumbed standard with Dual Stacked HydroGear Variable Displacement Pumps and Fixed Displacement Wheel Motors, avoiding the need for belts entirely.

The stand-on utility loader comes standard with a Heavy Duty 2-Stage Cyclonic Canister Air Filtration System. Having a 2-stage filtration system makes sure your engine pulls in clean air, acting as your engine’s shield in dusty conditions. Keep the filter clean to improve engine performance, fuel efficiency, and extend engine life.

Unique to the market, the Force’s new stand-on utility loader features advanced load sensors to detect and readjust functions if operators try to carry over the load capacity. These sensors are connected to a Kohler engine, and will force the machine to either slow down or stop to prevent it from tipping.

The Auxiliary Hydraulic Flow & Pressure Controls on our stand-on utility loader are featured with the front-mount attachments. From the controls, operators can redistribute more power to the machine’s front attachments for more aggressive, heavy-duty groundwork purposes.

FAQs

The main differences between a track system and a wheel system on a loader are weight distribution and working environment. Landscapers will choose a mini skid steer or mini-loader with a track system since these machines have more contact with the ground. This contact provides more grip and stability over soft soil or uneven surfaces. However, they cannot operate on flat surfaces, since concrete or asphalt will wear down the rubber tracks. Overall, these machines have a limited speed of 4mph.

By comparison, wheeled systems like those on the Force Stand-On Utility Loader offer better weight distribution and balance by having four contact points rather than one with a track. What’s more, the Force Stand-On Utility Loader’s unique system has zero-turn functionality, allowing the machine to make tight turns like a mini-loader or skid steer. Unlike mini-loaders, though, our stand-on utility loader has the traction and capability to run on dirt, concrete, asphalt, or icy surfaces with ease. Engineered to have a max speed of 8mph, the Force Stand-On Utility Loader has the advantage to work on multiple surfaces due to having a wheel system.

We advise against modifying the wheel system on our Stand-On Utility Loaders by adding rubber tracks. Not only could altering the wheels impact the machine’s driving capabilities, but it does not require a track system like other mini-loaders. With a wheelbase of 30”, our wheel system offers enough stability and traction for operators to work safely in many different environments. Unlike a mini-loader’s track system, the Stand-On Utility Loader works well on dirt, concrete, asphalt, ice, or other uneven surfaces. Adding a rubber track could also impact the machine’s zero-turn mobility and speed, preventing your utility loader from performing at its best.

In addition to ABI Force’s range of front-mount attachments, front-mount attachments from other mini-loader manufacturing companies can be used on your Stand-On Utility Loader. To pair non-Force front-mount attachments, we offer a universal mount plate which can be attached to your loader. Learn more details by speaking with one of our Force Product Specialists.